For any company that manages inventory, the struggle to maintain optimal inventory levels is a constant challenge. The high costs of overstocking and the lost revenue from understocking can significantly impact a company’s profitability. Having just the right balance of the right stock at the right location, when needed, is the key to inventory nirvana.

Inventory management ensures that just the right amount of goods are kept in inventory at any time. They need to be available at the right place at the right time, with minimal costs in moving them to that place. And they should not be more or less than what is needed. Having too much inventory means that working capital is tied up in the stock on hand. Having too little inventory or having it in the wrong place for it to be used on time, is of no use – the customer will not be able to access it and may have a worse overall experience.

For years, businesses have relied on manual processes or basic digital systems to manage their inventory, but these methods are often inefficient and prone to error. The future of inventory lies with artificial intelligence. AI driven inventory management is leading the charge in creating smarter, more efficient supply chains.

At the forefront of this revolution are AI Agents, autonomous systems that are set to redefine the way businesses manage their stock.

The role of AI in Inventory Management

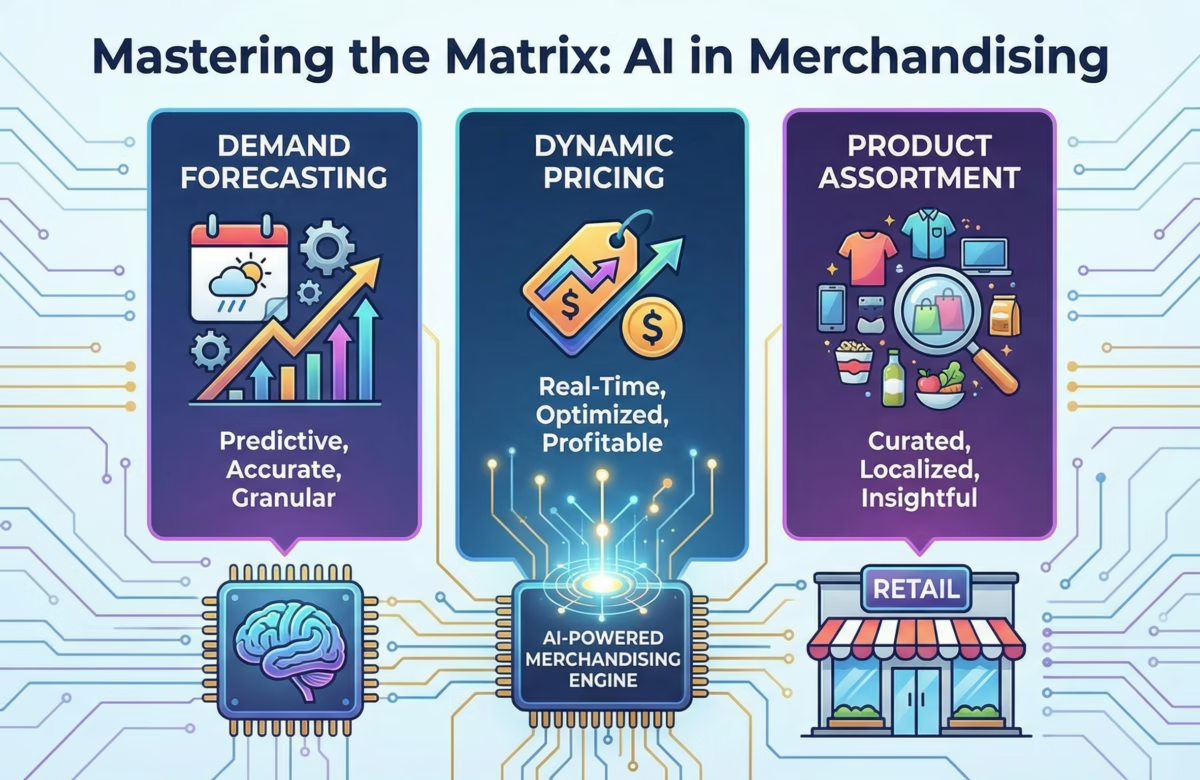

AI in inventory management is the application of artificial intelligence technologies to optimize and automate the inventory management process. Unlike traditional systems that rely on historical data and manual input, inventory management using AI leverages advanced technologies like machine learning and predictive analytics to forecast demand, optimize stock levels, and then use AI Agents to automate replenishment.

This shift from reactive to proactive inventory management allows businesses to make data-driven decisions, reduce costs, and improve customer satisfaction. The integration of inventory ai and ai and inventory management systems is transforming the industry, offering a level of precision and efficiency that was previously unattainable.

The Core Benefits of AI for Inventory Management

The adoption of AI for inventory management brings a multitude of benefits to businesses of all sizes. These advantages are not just incremental improvements; they represent a fundamental shift in how inventory is managed.

It is critical to use AI for inventory management purposes in order to have just the right stock on hand in the right place at the right time.

Here are some of the core benefits of AI for inventory management:

Predictive Forecasting

One of the most significant advantages of inventory management using machine learning is its ability to predict future demand with remarkable accuracy. By analysing historical sales data, seasonality, market trends, and even external factors like weather patterns and social media sentiment, AI algorithms can generate highly accurate demand forecasts. This allows businesses to optimize their inventory levels, preventing stockouts of popular items and reducing the overstocking of slow-moving products.

The predictions can also be done in a planned manner. How often is your supply chain able to efficiently deliver stock to a warehouse? Now using machine learning, you may be able to decide the best time to move stock that maximises the benefits and keeps the cost as low as needed while still solving the problem.

Automated Replenishment

AI inventory control systems can automate the entire replenishment process. By continuously monitoring stock levels in real-time, these systems can automatically trigger purchase orders when inventory falls below a predetermined threshold.

This not only reduces the manual workload for employees but also minimizes the risk of human error, ensuring that the right products are always in stock to meet customer demand. Of course, using the previous example – the right frequency of monitoring and of replenishment needs to be decided and won’t be the same for everyone.

Reduced Holding Costs

The benefits of AI in inventory are most evident in the reduction of holding costs. Overstocking can tie up a significant amount of capital in unsold goods as mentioned above, leading to increased storage costs and the risk of inventory obsolescence.

By optimizing stock levels and improving forecast accuracy, AI based inventory management systems help businesses minimize their inventory holding costs, freeing up capital for other strategic investments. This is a real reduction in operating costs, which means a better utilization of overall capital.

Enhanced Efficiency

By automating repetitive and time-consuming tasks, AI in inventory management significantly enhances operational efficiency. This allows employees to focus on more strategic initiatives, such as improving supplier relationships, negotiating better prices, and enhancing the overall customer experience.

Furthermore, the use of AI reduces the likelihood of human error in data entry and order processing, leading to a more accurate and reliable inventory management system.

The Game-Changer: AI Agents in Inventory Management

While AI-powered forecasting and automation are transforming inventory management, a new and even more powerful technology is emerging – AI Agents. These are not just simple automation tools; they are autonomous, intelligent entities that can perform complex, multi-step tasks without human intervention. AI Agents represent the next evolution of artificial intelligence in supply chain management, capable of making decisions and taking actions on their own.

Imagine an AI Agent that not only predicts a surge in demand for a particular product but also automatically sources the best supplier, negotiates a bulk price, and schedules the shipment, all while updating your inventory records in real-time. This is the power of AI Agents. They can analyse real-time shipping data, dynamically adjust pricing based on stock levels, and even manage returns autonomously. By offloading these complex and time-consuming tasks to AI Agents, businesses can achieve a level of efficiency and agility that was previously unimaginable.

Real-World Applications & Use Cases

The adoption of ai inventory management is already well underway, with many leading companies leveraging this technology to gain a competitive edge. Here are a few examples of how different industries are using AI to revolutionize their inventory management:

- Retail: Large retailers like Amazon and Walmart are pioneers in using AI for inventory management. They use sophisticated AI algorithms to forecast demand for millions of products, optimize their warehouse layouts, and even use robots to automate the picking and packing process. This allows them to deliver products to customers faster and more efficiently than ever before.

- Manufacturing: In the manufacturing sector, artificial intelligence in supply chain is being used to manage raw materials and implement just-in-time production. By accurately forecasting the demand for finished goods, manufacturers can ensure that they have the right amount of raw materials on hand, minimizing storage costs and reducing the risk of production delays.

- Logistics: Third-party logistics (3PL) providers are using AI inventory management to optimize their warehouse space and fulfillment processes. By analyzing data on product size, weight, and demand, AI systems can recommend the most efficient way to store and retrieve products, reducing labor costs and improving order accuracy.

Conclusion: Embracing the Future of Inventory

The era of manual, reactive inventory management is coming to an end. The future of inventory is intelligent, automated, and predictive, thanks to the power of AI and inventory management. From accurate demand forecasting to automated replenishment and the emergence of autonomous AI Agents, the possibilities are endless. By embracing AI-based inventory management, businesses can not only reduce costs and improve efficiency but also gain a significant competitive advantage in an increasingly automated world. The time to start exploring how AI can transform your inventory management is now. Contact Us